vickers hardness test journal|is 1501 pdf free download : wholesaling Vickers hardness is defined as the ratio of the force F acting on the diamond . Resultado da 13 de dez. de 2023 · O influenciador fitness Renato Cariani é investigado pela Polícia Federal, . Atirador de elite dispara na mão de homem que fazia filha refém. Criança foi resgatada sem ferimentos. Homem foi .

{plog:ftitle_list}

[18+] Os mais tesudos da Baixada Santista! Garotos lindos, r.

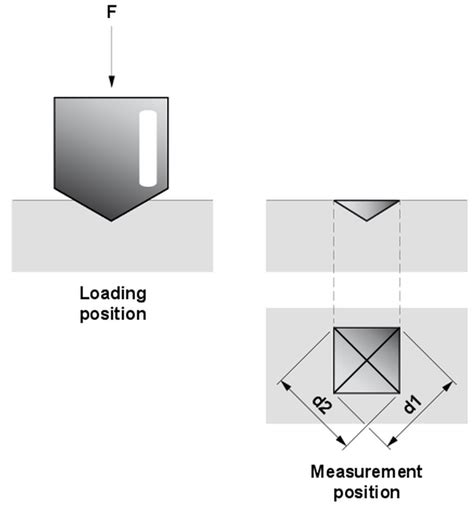

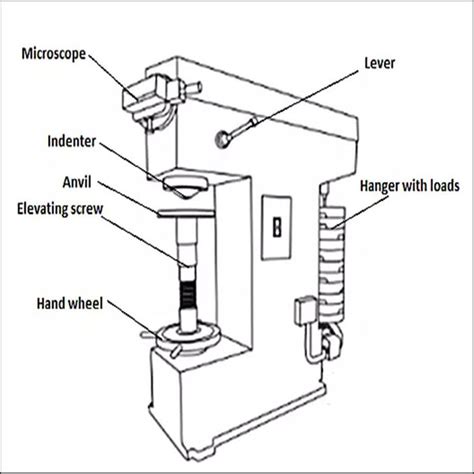

The Vickers hardness test or the 136 degree diamond pyramid hardness test is a microindentation method. The indenter produces a square indentation, the diagonals of which .Vickers hardness is defined as the ratio of the force F acting on the diamond .Vickers hardness is defined as the ratio of the force F acting on the diamond indenter (regular four-sided pyramid shape) and the surface A of the indentation (on the surface of the object . Vickers hardness testing is one of the most useful methods to determine the hardness of materials. To calculate the hardness of materials, the key is to measure the diagonal length of the.

We evaluate Vickers hardness and true instrumented indentation test (IIT) hardness of 24 metals over a wide range of mechanical properties using just IIT parameters . The Vickers hardness test [8] is commonly used to evaluate key mechanical properties of materials. Evaluation of the hardness value (HV) of a metallic material enables .

This analysis allows one to conclude that the semi-automatic measurement of Vickers and Brinell hardnesses by the computational approach is easier, faster, and less . This emphasizes the surface mechanical properties of Vickers hardness and the static friction coefficient, with attempts to model them as functions of stress at yield initiation. Vickers hardness can be related to the .

vickers hardness test procedure pdf

In this investigation, we built a successful machine learning model that implements Gradient Boosting Regressor (GBR) to predict hardness and uses the mechanical properties .Vickers hardness testing is one of the most useful methods to determine the hardness of a material. Vickers hardness values are obtained by forcing a pyramidal diamond indenter with .The Vickers hardness test was developed in 1924 by Smith and Sandland at Vickers Ltd. The hardness number, Vickers Pyramid Number, is determined by the load over the surface area .

Hardness is a useful measure of a material’s resistance to permanent indentation; but for viscoelastic polymers, hardness data are highly dependent on the test type and the parameter set chosen. Vickers .

Abstract. Mechanical hardness testing is fundamental in the evaluation of the mechanical properties of metallic materials due to the fact that the hardness values allow one to determine the wear resistance of the material involved, as well as the approximate values of its ductility and flow tension, among a number of other key characteristics. As a result, the main .Hardness testing within the realm of materials testing. Today, hardness testing is one of the most widely used methods in mechanical materials testing, especially for metals. On the one hand, this test method can be used to find .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . 1. Introduction. Hardness testing, defined as a test method to measure a material’s resistance to permanent indentation, was developed for metals but can be applied to polymers even though they exhibit a viscoelastic response that complicates the analysis [1,2].However, it is only after appropriate calibration and parameter selection that hardness .

kekerasan (Hardness Test) yang berupa uji kekerasan micro vickers dimana dalam pengujian kekerasan mikro itu digunakan indentor Vickers dan dilaksanakan berdasarkan standar ASTMN E384. Hasil dari pengukuran bekas indentasi dapat diketahui. Kata Kunci: Kekerasan, kekuatan, jenis material 1.PENDAHULUANVickers hardness test was undertaken in microhardness tester FM800 equipped with an optical system in the Department of Materials Engineering, Indian Institute of Science (IISC), Bengaluru. For this, all teeth were cut using an angular diamond disk at the cement enamel junction. This chapter discusses hardness testing. Hardness testing is a descriptive term for a number of methods for the measurement of the resistance of a surface to the action of a body which is forced into it under pressure or by means of an impact.

A Vickers hardness measurement as a function of depth for the graded composite sample from the graded A/CA 6 layer to the homogeneous alumina layer was performed on the surface of the polished sample using a Vickers indenter. Indentations were made at distances of approximately 1, 2.9, 4.2, 5.9, 7.6, 9.9, 12.3, 15.1, 17 and 18 mm.A load of 98 N was used to carry out this . where HV is the Vickers hardness [Pa], F the test load [N] and d the mean of the indentation diagonals [m].. Usually, the descriptive statistics is used for analyses of experimental data. Thus, measures such as the average and the standard deviation will be applied to the HV database, according to Eqs.2 and 3, respectively. Vickers hardness test uses a very small diamond indenter with a pyramidal geometry that has an angle of 136 \(^\circ\) between the plane faces of the indenter tip. The Vickers hardness measurement .

Abstract. Hardness is being assessed as a potential life-assessment tool for tracking microstructural degradation and remaining life in creep strength enhanced ferritic (CSEF) steels. Such methodology is already being utilized for the CSEF steel Grade 91, which has been widely implemented in both replacement parts and new construction over the last two .

To address the problem of poor accuracy associated with using instrumented indentation tests to determine Vickers hardness, and the problem of selection of the most appropriate instrumented indentation approach, the finite element method was adopted to determine theoretical Vickers hardness values of different materials. On the basis of these .

Hardness testing is of immense importance for quality assurance in industry. Although the most widely used hardness test methods for metals—Rockwell, Brinell, and Vickers—were developed between 1900 and 1925, numerous technical innovations have been made in recent years, leading to an increase in productivity and the accuracy of hardness tests. We evaluate Vickers hardness and true instrumented indentation test (IIT) hardness of 24 metals over a wide range of mechanical properties using just IIT parameters by taking into account the real contact morphology beneath the Vickers indenter. Correlating the conventional Vickers hardness, indentation contact morphology, and IIT parameters for the .The Vickers hardness test is often regarded as easier to use than other hardness tests: The process can be performed on a universal or micro hardness tester; the required calculations are independent of the size of the indenter; .

Tiryakioglu, M and Robinson, JS, On the representative strain in Vickers hardness testing of 7010 aluminum alloy. Materials Science and Engineering: A Structural Materials: Properties, Microstructure and Processing, 2015. . Haddow, JB, A study of Knoop hardness test. Journal of Basic Engineering, 1966. 88 (3): 682 –&.Google Scholar. 25 The Vickers hardness test is based on the principle of indentation hardness, where a diamond indenter with a square-based pyramid shape is pressed into the surface of the material under a specified load. The diagonals of the resulting indentation are measured using a microscope, and the Vickers hardness value is calculated using a formula that .

vickers hardness test manual

Hardness testing is an essential test in the metal manufacturing industry, and Vickers hardness is one of the most widely used hardness measurements today. The computer-assisted Vickers hardness test requires manually generating indentations for measurement, but the process is tedious and the measured results may depend on the operator’s .

Superalloys are high-temperature materials with outstanding strength and resistance to corrosion. A prior knowledge about its hardness is essential for development of new superalloys for its applications in aeronautics and power industries. Determining the hardness of a material with experiments is usually a destructive process. In this study, using structural, .In Vickers hardness test the depth of indentation have to be limited to a maximum of 10 % from average diagonal length of indent. . and Processes, 2012 April, p. 28-33. [3] Gong J., Wu J., Guan Z., Examination of indentation size effect in low-load Vickers hardness testing of ceramics, Journal of European Ceramic Society, 1999, 19(15) 2625 . Editors select a small number of articles recently published in the journal that they believe will be particularly interesting to readers, or important in the respective research area. . ASTM E92-17; Standard Test Methods for Vickers Hardness and Knoop Hardness of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2017; pp. 1 .

This basic book provides a comprehensive overview of hardness testing, including the various methods and equipment used, testing applications, and the selection of testing methods. The revised and updated second edition features expanded information on microhardness testing, specialized hardness tests; and hardness testing standards.Comparative Analysis of FCAW, and GMAW Welding With Heat Input Variations on A36 Steel Against Vickers Hardness Test and Macrostructure. In offshore building construction, a precise welding method is needed on A36 steel, where A36 steel is one of the main materials in the fabrication process of offshore buildings. . International Journal of .

ISO 6507-1 Metallic Materials—Vickers hardness Test— Part 1: Test Method 3.2.3 macroindention hardness test, n—a hardness test using ISO/IEC 17011 Conformity Assessment—General Require- test forces normally higher than 9.807 N (1 kgf). Macroinden- ments for Accreditation Bodies Accrediting Conformity tation tests include Vickers . Standardized Testing: Vickers hardness testing is commonly used in standardized testing methods, making it suitable for comparing hardness values across different materials. Macrohardness Testing: While primarily a microhardness test, Vickers hardness testing can also be adapted for macrohardness testing of larger samples.the hardness value is calculated based on the applied load and the indentation size. Vickers belongs to the optical methods. Vickers Hardness The Knoop hardness test is similar to the Vickers test but uses a rhombic-based diamond indenter instead of a pyr-amid. It is commonly used for measuring the hardness of thin

compression tester o reilly auto parts

rockwell hardness tester procedure pdf

17 de ago. de 2022 · Tufos completos. 17 de agosto de 2022 Por. Toda a gente quer saber tudo sobre tufos completos, mas pouca gente fala nisso.Mas temos que discutir a noção .

vickers hardness test journal|is 1501 pdf free download